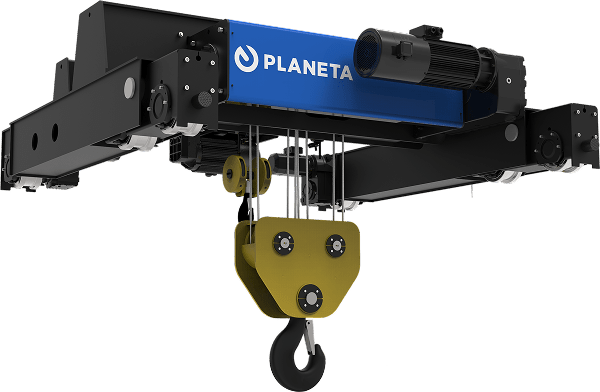

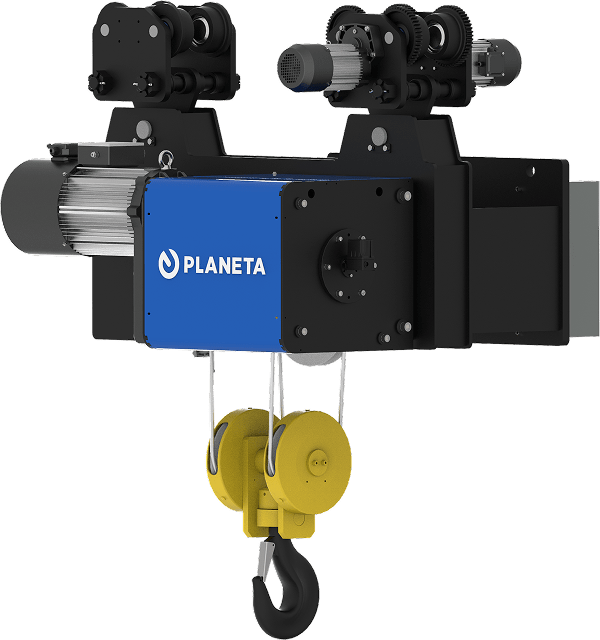

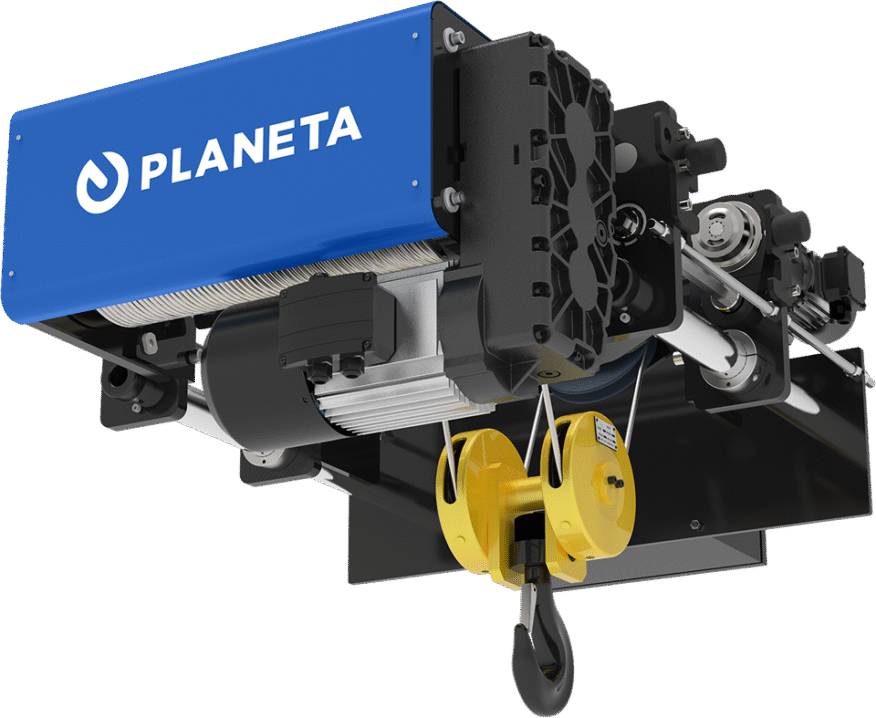

PLANETA PWRH Electric Wire Rope Hoists

Maximum Performance. Minimal Footprint. Unmatched Efficiency.

Our electric wire rope hoists are engineered to streamline your processes, significantly lower your operating costs, and provide long-term improvements in occupational safety – even under the toughest conditions.

When space is tight, energy costs keep climbing and outdated wire rope hoists compromise safety, your entire operation is at risk. It’s time for a smarter, safer and more efficient lifting solution.

PLANETA electric wire rope hoists deliver what modern industry demands: compact design, powerful performance and maximum efficiency. For those who can’t afford downtime and need to lift with confidence, it’s the smart choice that moves more than just loads – it moves your business forward.

certified quality

certified quality

Maximum lifting capacity

Catalog & Technical Data – Everything You Need in One Place

Download our latest catalog as a PDF and explore detailed specifications, configuration options, and in-depth information about our electric wire rope hoists.

Your Personal Contact at PLANETA

Thomas Steffen

Whether you have initial questions, specific requirements or a concrete project in mind – we’re here for you. Your dedicated PLANETA contact will support you from first consultation to the finished solution. Benefit from expert knowledge, fast response times, and a partnership built on trust and understanding.

Built for continuous industrial operation.

Quick to Install. Efficient in Use. Low Maintenance by Design.

FAQ

How energy-efficient are PLANETA electric wire rope hoists?

Equipped with modern, high-performance motors, our hoists deliver strong lifting power while consuming minimal energy – ideal for continuous operation with reduced electricity costs.

What maintenance intervals are required?

PLANETA hoists are engineered to be low-maintenance. Exact intervals depend on your operating conditions – we’re happy to provide a customized maintenance plan on request.

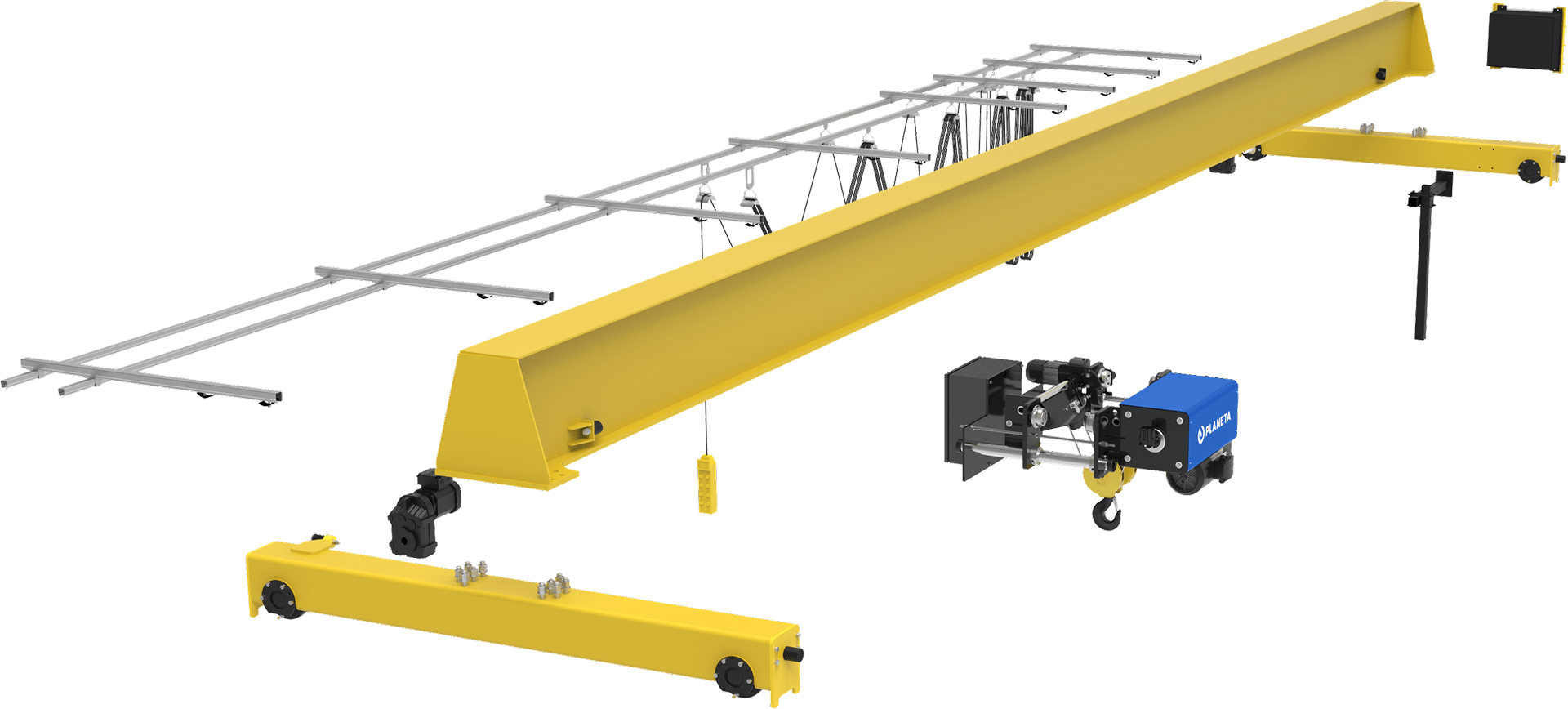

Can I Order the Wire Rope Hoist as Part of a Complete Crane System?

Absolutely! We offer the electric wire rope hoist as a fully equipped crane kit – including end carriages, motorised trolley, control unit (wired or radio), electrical cabinet, buffers, C-rail system, trailing cable power supply, and collector support. This all-in-one solution saves you time and planning costs – and delivers a seamlessly integrated, low-maintenance lifting system that’s ready for industrial performance.

Is the technology compatible with existing systems?

Yes, our electric wire rope hoists are modular and can be easily integrated into existing crane or production systems – even in complex environments.

What load capacities can be covered?

Depending on the model, PLANETA electric wire rope hoists can handle loads from 1,000 to 80,000 kg. Various configurations and designs are available to meet your specific requirements.

Is support available when choosing the right model?

Absolutely. Our experts offer personal consultation and will help you identify the optimal solution based on your industry, environment and process needs.

What control options are available?

PLANETA hoists can be operated via push-button pendant, radio remote control or integrated into a complete crane package – giving you maximum flexibility.

Are custom solutions possible?

Yes, we offer tailored adaptations for special applications. From reduced headroom to custom load handling attachments or advanced control systems – our team will develop a solution that fits your needs.

How is safety ensured with PLANETA hoists?

All models include built-in safety features such as overload protection, limit switches and robust rope guides. Optional features like load monitoring and anti-sway systems are also available for enhanced operational safety.

How quickly can a PLANETA electric wire rope hoist be put into operation?

Thanks to a compact design, pre-assembled components and straightforward installation, setup is quick and efficient – often completed within just a few hours.

Turning products into exceptional service

Service is in our DNA – from initial consultation and feasibility studies to custom engineering, production, maintenance, inspection and repair. We’re your reliable partner for even the most demanding projects.

About PLANETA

Engineering Innovation with Tradition –

Since 1861

A Legacy of Lifting – Since 1861

Challenge: Gravity

PLANETA represents the perfect blend of tradition and forward-thinking innovation in the world of lifting technology. Our roots go back to 1861, when master locksmith Hermann Wilhelmi opened his own workshop in Mülheim an der Ruhr – laying the foundation for what would later become the renowned lifting equipment company Wilhelmi, now known as PLANETA Hebetechnik since 2003.

Driven by an unwavering pursuit of precision, our products soon shaped not only individual workshops, but entire industries. Branches in Paris, Vienna and Shanghai followed, becoming key hubs in our global network and expressions of our international expertise.

Quality and safety have always been the driving forces behind our growth. Our certifications according to DIN EN ISO 9000:2001 and strict Occupational Health and Safety (OHS) standards are not just framed certificates – they are promises embedded in every PLANETA product and service.

Today, PLANETA doesn’t just follow the evolution of lifting technology – we help shape it. Our goal is to perfect every detail, so our hoists not only lift heavy loads, but also elevate safety, efficiency and technical progress for our customers around the world.

certified quality

Standardized processes and the highest quality standards have been the foundation of our commitment and identity – for more than 150 years.

Challenge Gravity – with lifting and moving solutions designed for maximum efficiency.

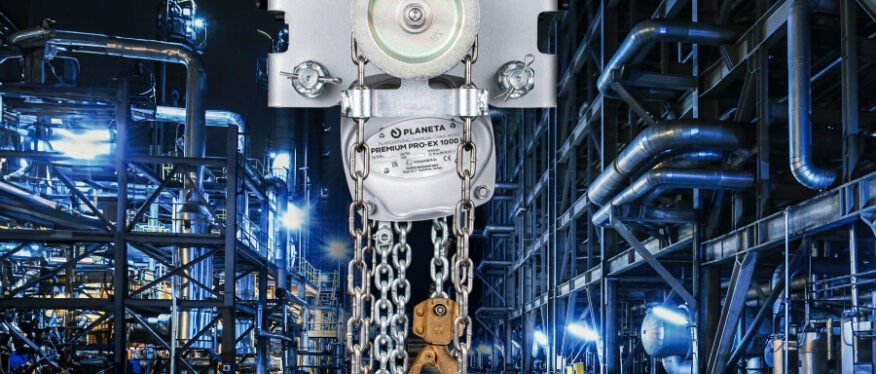

Lifting technology

Discover our wide range of hoist products that enable you to work safely and efficiently. Whether manually operated hoists or electric chain hoists – our expertise secures your project with robust and reliable technology.

Cable winches

Maximize your productivity with our cable winches. Designed for precision and strength, they are the ideal choice for demanding applications. Quality is the focus of every production process.

Let’s Find the Right Hoist for Your Needs

Looking to reduce downtime, save energy, and optimise your production? Our electric wire rope hoists are built for exactly that. Let’s find the right solution for your application – fast, tailored, and hassle-free.